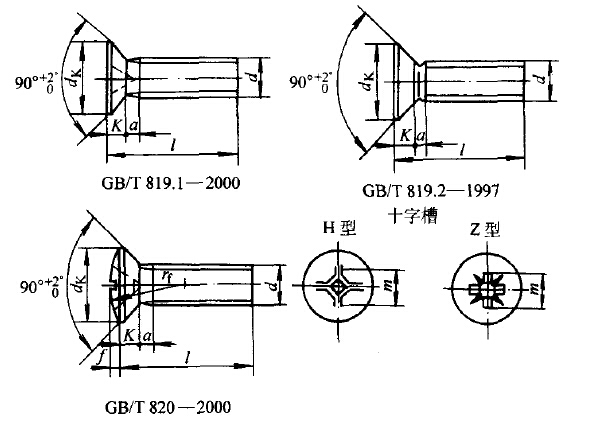

6 十字槽沉头螺钉和十字槽半沉头螺钉GB/T 819、GB/T 820—2000标准

十字槽沉头螺钉和十字槽半沉头螺钉GB819、GB820—2000标准

国标原文档下载:GB/T 819.1-2016.pdf,GB/T 819.2-2016.pdf,GB/T820-2000.pdf,GB/T820-2015.pdf

替代标准下载:ISO7046-1-2011.pdf,ISO7046-2-2011.pdf

十字槽沉头螺钉和十字槽半沉头螺钉的尺寸规格、质量见表4.2-11〜表4.2-13。

表4.2-11 十字槽沉头螺钉和十宇槽半沉头螺钉的尺寸规格(mm)

用途:

与开槽沉头螺钉和开槽半沉头螺钉相同。其特点是头部制成十字槽,槽形强度好,便于实现自动化装拆螺钉。

| 螺纹规格d (6 g) | Ml.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | M8 | M10 | |||||

| a max | 0.7 | 0.8 | 0.9 | 1 | 1.2 | 1.4 | 1.6 | 2 | 2.5 | 3 | |||||

| b min | 25 | 25 | 25 | 25 | 38 | 38 | 38 | 38 | 38 | 38 | |||||

| dk max | 3 | 3.8 | 4.7 | 5.5 | 7.3 | 8.4 | 9.3 | 11.3 | 15.8 | 18.3 | |||||

| K max | 1 | 1.2 | 1.5 | 1.65 | 2.35 | 2.7 | 2.7 | 3.3 | 4.65 | 5 | |||||

| rf ≈ | 3 | 4 | 5 | 6 | — | 9.5 | 9.5 | 12 | 16.5 | 19.5 | |||||

| 十字槽 | 槽号No | 0 | 1 | 2 | 3 | 4 | |||||||||

| 插入深度 | GB/T 819.1 | H型 | min | 0.6 | 0.9 | 1.4 | 1.7 | — | 2.1 | 2.7 | 3 | 4 | 5.1 | ||

| max | 0.9 | 1.2 | 1.8 | 2.1 | — | 2.6 | 3.2 | 3.5 | 4.6 | 5.7 | |||||

| Z型 | min | 0.7 | 0.95 | 1.45 | 1.6 | — | 2.05 | 2.6 | 3 | 4.15 | 5.2 | ||||

| max | 0.95 | 1.2 | 1.75 | 2 | — | 2.5 | 3.05 | 3.45 | 4.6 | 5.65 | |||||

| GB/T 819.2 | 系列1 | H型 | min | — | 0.9 | 1.4 | 1.7 | 1.9 | 2.1 | 2.7 | 3 | 4 | 5.1 | ||

| max | — | 1.2 | 1.8 | 2.1 | 2.4 | 2.6 | 3.2 | 3.5 | 4.6 | 5.7 | |||||

| Z型 | min | — | 0.95 | 1.48 | 1.76 | 1.75 | 2.06 | 2.6 | 3 | 4.15 | 5.19 | ||||

| max | — | 1.2 | 1.73 | 2.01 | 2.2 | 2.51 | 3.05 | 3.45 | 4.6 | 5.64 | |||||

| 系列2 | H型 | min | — | 0.9 | 1.25 | 1.4 | 1.6 | 2.1 | 2.3 | 2.8 | 3.9 | 4.8 | |||

| max | — | 1.2 | 1.55 | 1.8 | 2.1 | 2.6 | 2.8 | 3.3 | 4.4 | 5.3 | |||||

| Z型 | min | — | 0.95 | 1.22 | 1.48 | 1.61 | 2.06 | 2.27 | 2.73 | 3.87 | 4.78 | ||||

| max | — | 1.2 | 1.47 | 1.73 | 2.05 | 2.51 | 2.72 | 3.18 | 4.32 | 5.23 | |||||

| GB/T 820 | H型 | min | 0.9 | 1.2 | 1.5 | 1.8 | — | 2.7 | 2.9 | 3.5 | 4.75 | 5.5 | |||

| max | 1.2 | 1.5 | 1.85 | 2.2 | — | 3.2 | 3.4 | 4 | 5.25 | 6 | |||||

| Z型 | min | 0.95 | 1.15 | 1.5 | 1.8 | — | 2.65 | 2.9 | 3.4 | 4.75 | 5.6 | ||||

| max | 1.2 | 1.4 | 1.75 | 2.1 | — | 3.1 | 3.35 | 3.85 | 5.2 | 6.05 | |||||

| l① 商品规格范围 | 3~16 | 3〜 20 | 3〜 25 | 4~30 | 5~35 | 5〜40 | 6~50 | 8~60 | 10~60 | 12~60 | |||||

注:1.仅GB/T 819.2有(M3.5)的规格。

2. GB/T819.1为钢4.8; GB/T819.2为钢8.9、不锈钢A2-70和有色金属CU2、CU3; GB/T 820为钢4.8和不锈钢A2-70、A2-50。

①公称长度系列为:3、4、5、6〜16(2进级)、20〜60 mm (5 mm进级)。

表4.2-12 钢4.8级十字槽沉头螺钉的质量(kg)

每1000件钢制品的大约质量

| l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G |

| Ml.6 | M2 | M2.5 | M3 | M (3.5) | M4 | M5 | M6 | M8 | M10 | ||||||||||

| 3 | 0.058 | 3 | 0.101 | 3 | 0.176 | 4 | 0.291 | 5 | 0.573 | 5 | 0.825 | 6 | 1.24 | 8 | 2.38 | 10 | 5.68 | 12 | 9.54 |

| 4 | 0.069 | 4 | 0.119 | 4 | 0.206 | 5 | 0.335 | 6 | 0.633 | 6 | 0.903 | 8 | 1.48 | 10 | 2.73 | 12 | 6.32 | (14) | 10.6 |

| 5 | 0.081 | 5 | 0.137 | 5 | 0.236 | 6 | 0.379 | 8 | 0.753 | 8 | 1.06 | 10 | 1.72 | 12 | 3.08 | (14) | 6.96 | 16 | 11.6 |

| 6 | 0.093 | 6 | 0.152 | 6 | 0.266 | 8 | 0.467 | 10 | 0.873 | 10 | 1.22 | 12 | 1.96 | (14) | 3.43 | 16 | 7.6 | 20 | 13.6 |

| 8 | 0.116 | 8 | 0.193 | 8 | 0.326 | 10 | 0.555 | 12 | 0.993 | 12 | 1.37 | (14) | 2.2 | 16 | 3.78 | 20 | 8.88 | 25 | 16.1 |

| 10 | 0.139 | 10 | 0.231 | 10 | 0.386 | 12 | 0.643 | (14) | 1.11 | (14) | 1.53 | 16 | 2.44 | 20 | 4.48 | 25 | 10.5 | 30 | 18.7 |

| 12 | 0.162 | 12 | 0.268 | 12 | 0.446 | (14) | 0.731 | 16 | 1.23 | 16 | 1.68 | 20 | 2.92 | 25 | 5.36 | 30 | 12.1 | 35 | 21.2 |

| (14) | 0.185 | (14) | 0.306 | (14) | 0.507 | 16 | 0.82 | 20 | 1.47 | 20 | 2 | 25 | 3.52 | 30 | 6.23 | 35 | 13.7 | 40 | 23.7 |

| 16* | 0.208 | 16 | 0.343 | 16 | 0.567 | 20 | 0.90% | 25 | 1.77 | 25 | 2.39 | 30 | 4.12 | 35 | 7.11 | 40 | 15.3 | 45* | 26.2 |

| 20′ | 0.417 | 20 | 0.687 | 25 | 1.22 | 30 | 2.07 | 30 | 2.78 | 35 | 4.72 | 40 | 7.98 | 45* | 16.9 | 50 | 28.8 | ||

| 25* | 0.838 | 30* | 1.44 | 35* | 2.37 | 35 | 3.17 | 40 | 5.32 | 45* | 8.86 | 50 | 18.5 | (55) | 31.3 | ||||

| 40* | 3.56 | 45* | 5.92 | 50 | 9.73 | (55) | 20.1 | 60 | 33.8 | ||||||||||

| 50 | 6.52 | (55) | 10.6 | 60 | 21.7 | ||||||||||||||

| 60 | 11.5 | ||||||||||||||||||

注:1. l小于或等于带*号的螺钉,制出全螺纹。

2.表列规格为商品规格。尽可能不采用括号内的规格。

表4.2-13 十字槽半沉头螺钉的质量(kg)

每1000件钢制品的大约质量

| l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G | l | G |

| Ml.6 | M2 | M2.5 | M3 | (M3.5) | M4 | M5 | M6 | M8 | M10 | ||||||||||

| 3 | 0.067 | 3 | 0.119 | 3 | 0.212 | 4 | 0.351 | 5 | 0.669 | 5 | 0.99 | 6 | 1.49 | 8 | 2.79 | 10 | 6.89 | 12 | 11.4 |

| 4 | 0.078 | 4 | 0.138 | 4 | 0.242 | 5 | 0.395 | 6 | 0.729 | 6 | 1.07 | 8 | 1.73 | 10 | 3.14 | 12 | 7.53 | (14) | 12.5 |

| 5 | 0.09 | 5 | 0.156 | 5 | 0.272 | 6 | 0.439 | 8 | 0.849 | 8 | 1.23 | 10 | 1.97 | 12 | 3.49 | (14) | 8.17 | 16 | 13.5 |

| 6 | 0.102 | 6 | 0.175 | 6 | 0.302 | 8 | 0.527 | 10 | 0.969 | 10 | 1.39 | 12 | 2.21 | (14) | 3.84 | 16 | 8.81 | 20 | 15.5 |

| 8 | 0.125 | 8 | 0.212 | 8 | 0.362 | 10 | 0.615 | 12 | 1.09 | 12 | 1.54 | (14) | 2.45 | 16 | 4.19 | 20 | 10.1 | 25 | 18 |

| 10 | 0.145 | 10 | 0.249 | 10 | 0.422 | 12 | 0.703 | (14) | 1.21 | (14) | 1.7 | 16 | 2.69 | 20 | 4.89 | 25 | 11.7 | 30 | 20.6 |

| 12 | 0.165 | 12 | 0.287 | 12 | 0.482 | (14) | 0.791 | 16 | 1.33 | 16 | 1.85 | 20 | 3.17 | 25 | 5.77 | 30 | 13.3 | 35 | 23.1 |

| (14) | 0.185 | (14) | 0.325 | (14) | 0.543 | 16 | 0.879 | 20 | 1.57 | 20 | 2.17 | 25 | 3.77 | 30 | 6.64 | 35 | 14.9 | 40 | 25.6 |

| 16* | 0.205 | 16 | 0.362 | 16 | 0.603 | 20 | 1.06 | 25 | 1.87 | 25 | 2.56 | 30 | 4.37 | 35 | 7.52 | 40 | 16.5 | 45* | 28.1 |

| 20* | 0.436 | 20 | 0.723 | 25 | 1.28 | 30 | 2.17 | 30 | 2.95 | 35 | 4.97 | 40 | 8.39 | 45* | 18.1 | 50 | 30.7 | ||

| 25* | 0.874 | 30* | 1.5 | 35* | 2.47 | 35 | 3.34 | 40 | 5.57 | 45* | 9.27 | 50 | 19.7 | (55) | 33.2 | ||||

| 40* | 3.73 | 45* | 6.16 | 50 | 10.1 | (55) | 21.3 | 60 | 35.7 | ||||||||||

| 50 | 6.76 | (55) | 11 | 60 | 22.9 | ||||||||||||||

| 60 | 11.9 | ||||||||||||||||||

注:1. l小于或等于带*号的螺钉,制出全螺纹。

2.表列规格为商品规格。尽可能不采用括号内的规格。