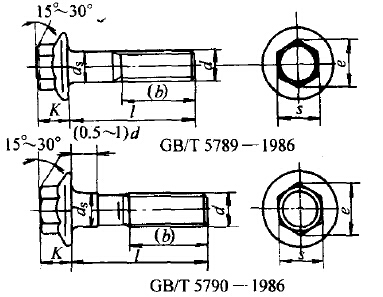

6 B级六角法兰面螺栓GB/T 5789、GB/T 5790—1986标准

B级六角法兰面螺栓GB5789、GB5790标准

B级六角法兰面螺栓的尺寸规格、质量见表4.1-7〜表4.1-9。

表4.1-7 B级六角法兰面螺栓的尺寸规格(mm)

用途:

防松性能好,能承受较高的预紧力,广泛用于汽车发动机、重型机械等产品

| 螺纹规格 d (6g) | M5 | M6 | M8 | M10 | M12 | (M14) | M16 | M20 | |

| b(参考) | l≤125 | 16 | 18 | 22 | 26 | 30 | 34 | 38 | 46 |

| 125< l≤200 | — | — | 28 | 32 | 36 | 40 | 44 | 52 | |

| da max | A型 | 5.7 | 6.8 | 9.2 | 11.2 | 13.7 | 15.7 | 17.7 | 22.4 |

| B型 | 6.2 | 7.4 | 10 | 12.6 | 15.2 | 17.7 | 20.7 | 25.7 | |

| c min | 1 | 1.1 | 1.2 | 1.5 | 1.8 | 2.1 | 2.4 | 3 | |

| dc max | 11.8 | 14.2 | 18 | 22.3 | 26.6 | 30.5 | 35 | 43 | |

| du max | 5.5 | 6.6 | 9 | 11 | 13.5 | 15.5 | 17.5 | 22 | |

| ds max | 5 | 6 | 8 | 10 | 12 | 14 | 16 | 20 | |

| f max | 1.4 | 2 | 3 | 4 | |||||

| e min | 8.56 | 10.8 | 14.08 | 16.32 | 19.68 | 22.58 | 25.94 | 32.66 | |

| K max | 5.4 | 6.6 | 8.1 | 9.2 | 10.4 | 12.4 | 14.1 | 17.7 | |

| S max | 8 | 10 | 13 | 15 | 18 | 21 | 24 | 30 | |

| l①长度范围 | GB/T 5789 | 10 ~50 | 12〜60 | 16〜80 | 20~100 | 25〜120 | 30~140 | 35 ~160 | 40〜200 |

| GB/T 5790 | 30〜50 | 35〜60 | 40〜80 | 45〜100 | 50~120 | 55 ~140 | 60〜160 | 70〜200 | |

注:尽可能不采用括号内的规格。

①公称长度系列为10、12、16、20〜50(5进级)、(55)、60、(65)、70〜200mm (10mm进级)。

表4.1-8 B级加大系列六角头法兰面螺栓的质量(kg)

| 每1000件钢制品的大约质量 | |||||||||||||||

| l | G | l | G | l | G | l | 0 | l | G | l | G | l | G | l | G |

| M5 | M6 | M8 | M10 | M12 | (M14) | M16 | M20 | ||||||||

| 10 | 2.98 | 12 | 5.44 | 16 | 11.96 | 20 | 20.89 | 25 | 35.99 | 30 | 67.67 | 35 | 88.45 | 40 | 165.6 |

| 12 | 3.22 | 16 | 6.12 | 20 | 13.2 | 25 | 23.34 | 30 | 39.55 | 35 | 74.21 | 40 | 95 | 45 | 175.9 |

| 16 | 3.70 | 20 | 6.81 | 25 | 14.76 | 30 | 25.8 | 35 | 43.11 | 40 | 80.76 | 45 | 101.5 | 50 | 186.1 |

| 20 | 4.18 | 25 | 7.67 | 30 | 16.31 | 35 | 28.26 | 40 | 46.68 | 45 | 87.3 | 50 | 108.1 | (55) | 196.3 |

| 25 | 4.89 | 30 | 8.78 | 35 | 18.27 | 40 | 31.33 | 45 | 51.05 | 50 | 93.84 | (55) | 114.6 | 60 | 206.6 |

| 30 | 5.60 | 35 | 9.81 | 40 | 20.13 | 45 | 34.26 | 50 | 55.27 | (55) | 98.7 | 60 | 123.7 | (65) | 216.8 |

| 35 | 6.31 | 40 | 10.85 | 45 | 21.98 | 50 | 37.19 | (55) | 59.48 | 60 | 104.5 | (65) | 131.2 | 70 | 230.8 |

| 40 | 7.03 | 45 | 11.89 | 50 | 23.84 | (55) | 40.12 | (60) | 63.7 | (65) | 110.2 | 70 | 138.8 | 80 | 254.5 |

| 45 | 7.74 | 50 | 12.93 | (55) | 25.69 | 60 | 43.05 | (65) | 67.91 | 70 | 116 | 80 | 154 | 90 | 278.2 |

| 50 | 8.45 | (55) | 13.96 | 60 | 27.54 | (65) | 45.98 | 70 | 72.13 | 80 | 127.6 | 90 | 169.1 | 100 | 301.9 |

| 60 | 15 | (65) | 29.4 | 70 | 48.91 | 80 | 80.55 | 90 | 139.1 | 100 | 184.3 | 110 | 325.6 | ||

| 70 | 31.25 | 80 | 54.77 | 90 | 88.98 | 100 | 150.7 | 110 | 199.4 | 120 | 349.3 | ||||

| 80 | 34.96 | 90 | 60.62 | 100 | 97.41 | 110 | 162.2 | 120 | 214.6 | 130 | 371 | ||||

| 100 | 66.48 | 110 | 105.8 | 120 | 173.8 | 130 | 228.5 | 140 | 394.7 | ||||||

| 120 | 114.3 | 130 | 186.2 | 140 | 243.7 | 150 | 418.4 | ||||||||

| 140 | 197.8 | 150 | 258.8 | 160 | 442.1 | ||||||||||

| 160 | 274 | 180 | 489.6 | ||||||||||||

| 200 | 537 | ||||||||||||||

注:表列规格为商品规格。尽可能不采用括号内的规格。

表4.1-9 B级细杆加大系列六角头法兰面螺栓的质量(kg)

| 每1000件钢制品的大约质量 | |||||||||||||

| l | G | l | G | l | G | l | G | l | G | l | G | l | G |

| M5 | M8 | M10 | M12 | (M14) | M16 | M20 | |||||||

| 30 | 5.49 | 40 | 19.9 | 45 | 34.11 | 50 | 55.37 | (55) | 98.23 | 60 | 124.5 | 70 | 233.5 |

| 35 | 6.09 | 45 | 21.46 | 50 | 36.57 | (55) | 58.93 | 60 | 104.8 | (65) | 131 | 80 | 254 |

| 40 | 6.69 | 50 | 23.01 | (55) | 39.03 | 60 | 62.49 | (65) | 111.3 | 70 | 137.6 | 90 | 274.5 |

| 45 | 7.29 | (55) | 24.57 | 60 | 41.48 | (65) | 66.05 | 70 | 117.9 | 80 | 150.7 | 100 | 294.9 |

| 50 | 7.89 | 60 | 26.12 | (65) | 43.94 | 70 | 69.61 | 80 | 131 | 90 | 163.7 | 110 | 315.4 |

| M6 | (65) | 27.68 | 70 | 46.39 | 80 | 76.74 | 90 | 144 | 100 | 176.8 | 120 | 335.9 | |

| 35 | 9.6 | 70 | 29.23 | 80 | 51.31 | 90 | 83.86 | 100 | 157.1 | 110 | 189.9 | 130 | 356.4 |

| 40 | 10.45 | 80 | 32.34 | 90 | 56.22 | 100 | 90.99 | 110 | 170.2 | 120 | 203 | 140 | 376.8 |

| 45 | 11.31 | 100 | 61.13 | 110 | 98.11 | 120 | 183.3 | 130 | 216.1 | 150 | 397.8 | ||

| 50 | 12.17 | 120 | 105.2 | 130 | 196.4 | 140 | 229.2 | 160 | 417.8 | ||||

| (55) | 13.03 | 140 | 209.5 | 150 | 242.3 | 180 | 458.8 | ||||||

| 60 | 13.88 | 160 | 255.3 | 200 | 499.7 | ||||||||

注:表列规格为商品规格。尽可能不采用括号内的规格